Production

Performance

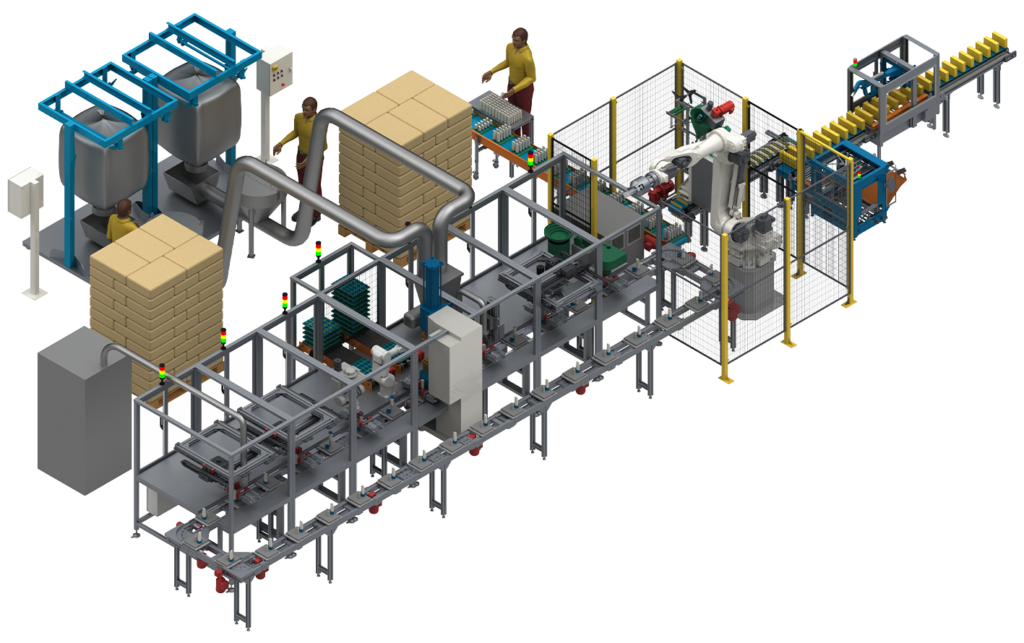

Working cycle of a conveyor

Water filters

6 filters/min - 360 filters/hour

15s material

Project description

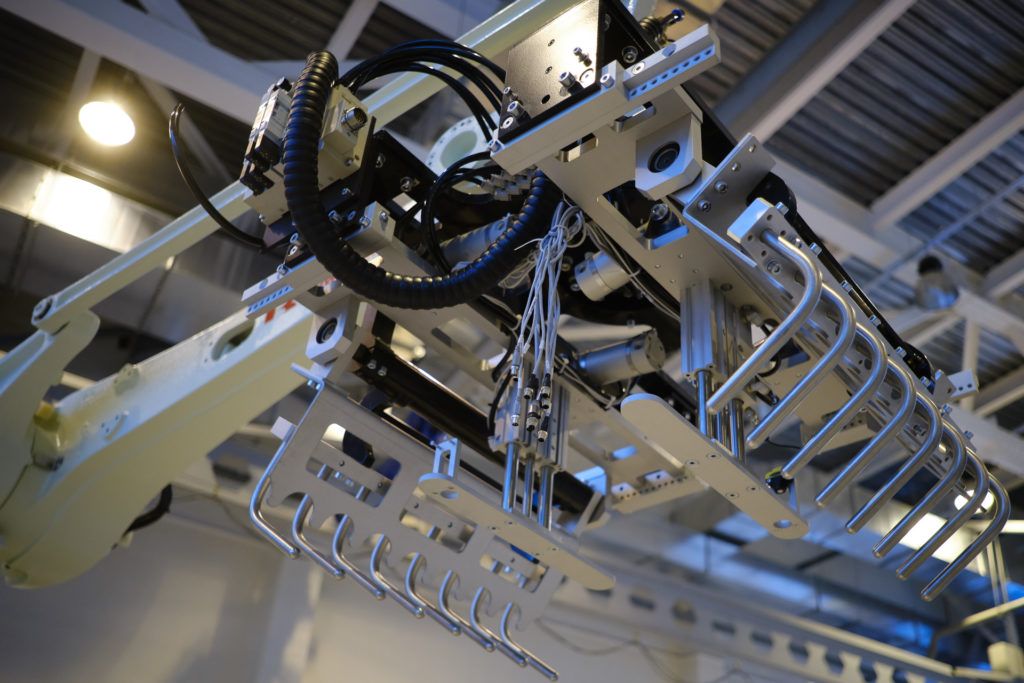

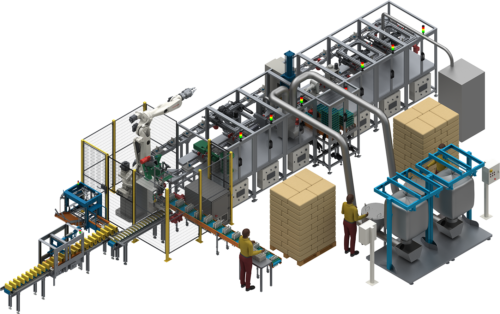

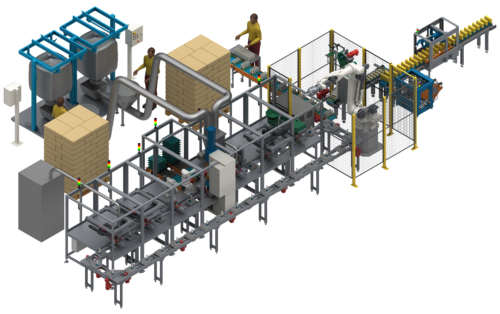

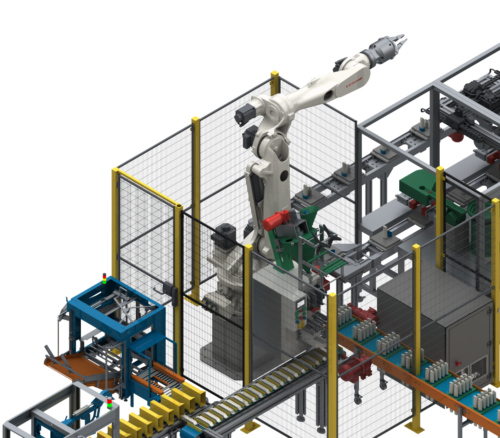

The main task of the line is to automatically fold the filter and pack it. In the first stage, the operator places the cast body on a conveyor belt, where it is transported for further assembly. The robot places the bodies onto a pallet conveyor, which moves the bodies to subsequent assembly stations. The body is fitted with an o-ring and then the body is filled with filter bed. The bed is supplied to the dosing unit by screw feeders, which are refilled from bags by operators. In the next step, the lower part of the filter is fed and welded. At this manufacturing stage, the filter undergoes a leak test and steam sterilization. The finished filter is delivered to the foiling station and packed 3 pieces per package using a pallet conveyor. The robot’s task is to deliver the bodies, pick up the finished filters and transfer them to the filming machine, where they are subsequently packaged.

info@autoproces.pl

info@autoproces.pl

+48 14 692 68 40

+48 14 692 68 40

Shop

Shop

Back

Back