Robotic Case Packing and Palletizing

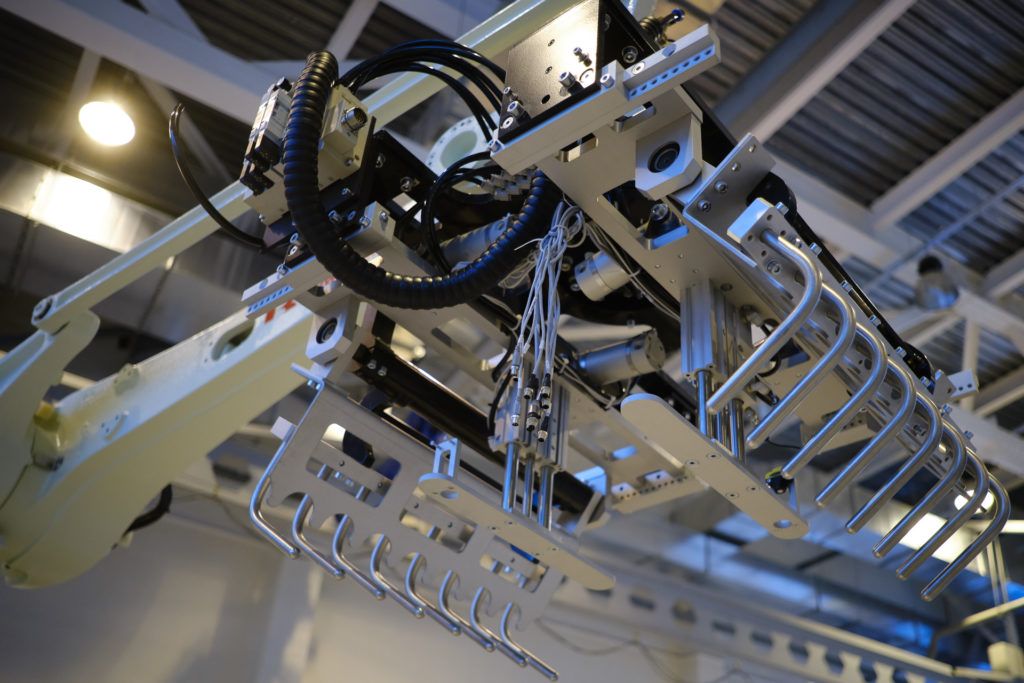

High-Speed Automated Assembly Machines

Production automation

Industrial IT

Autoproces

OUR WORK IS OUR PASSION.

We automate and robotize production processes, build machine assemblies, test and implement industrial systems.

We follow the principle: INNOVATION HAS NO LIMITS, we want to create solutions that will reach beyond the horizon, ahead of the needs of our clients.

We are looking for the most optimal and the best tools, also in terms of robotization and production automation.

We comprehensively implement the assumptions of Industry 4.0 in the field of production automation, starting from the project, through simulations and programming, to the construction of the line and commissioning.

We implement development projects that enable the creation of effective solutions in the production area. We plan the actual production layouts using simulations, integrating the existing systems into it.

info@autoproces.pl

info@autoproces.pl

+48 14 692 68 40

+48 14 692 68 40

Shop

Shop